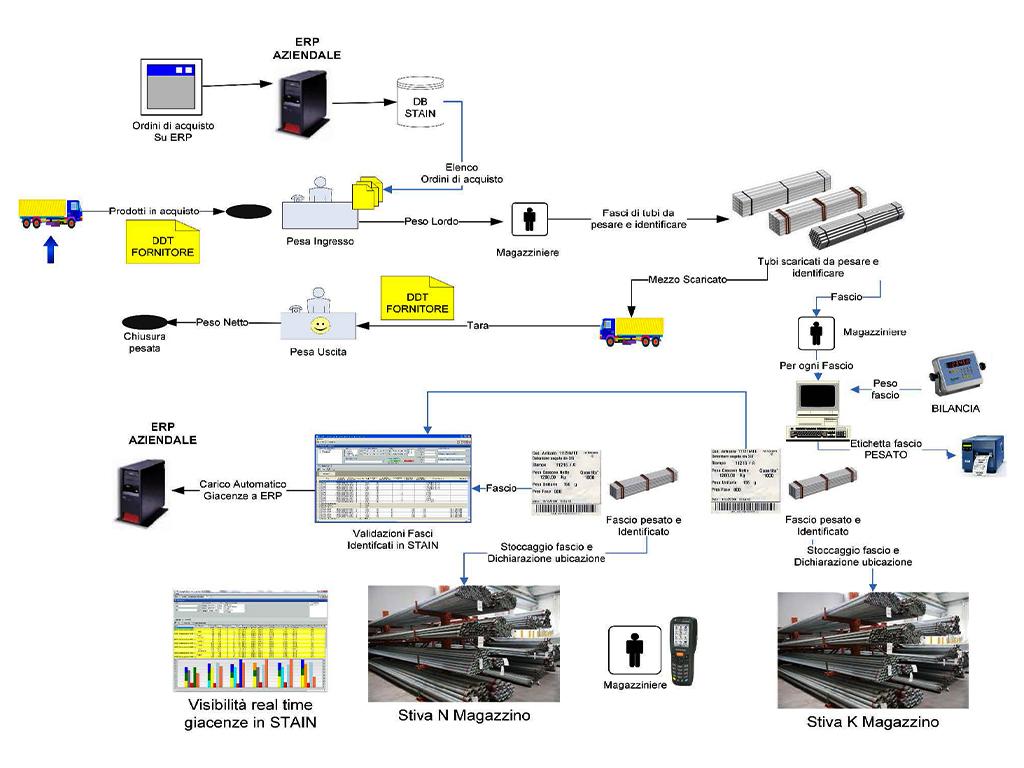

Incoming material management

- Automatic upload of material purchase orders from in-house ERP.

- Identification of vehicles at the weighbridge, automatic association of gross weight and purchase orders with incoming documents of transport (DTT).

- Visibility of vehicles at the plant and their status in real time.

- Unloading and weighing of bundles, univocal identification of each bundle (characteristics, heat, etc.) and association of the test certificate received by the supplier for each heat.

- Storage of the bundle in the warehouse and identification of the location with mobile handheld terminals.

- Weighing of outgoing vehicles and verification of weights declared in the transport documents with the actual weights measured.

Warehousing

- Location management for immediate view, status and position of each batch.

- Analysis of materials availability based on purchase orders, goods sold and cutting operations.

- Tracking and display of all the movements performed on individual production orders.

- Analysis of good in stock and movements using INTELLIGRID technology, that allows the user to create customised filters, pivot diagrams, multi-dimensional graphs, conditional formatting.

- Management of warehouse movements with mobile handheld terminals.

- Inventory management with mobile handheld terminals.

Material shipping management

- Automatic upload from in-house ERP of sales orders for shipment preparation.

- Computerization of deliveries (packing list).

- Computerization of transports.

- Real-time control of the compatibility of material collected with respect to material to be shipped, preventing loading errors and non-compliance on the status of the material loaded.

- Location visibility of the material to be collected for each packing list.

- Logging of the overall vehicle weight and the sum of weights of each batch loaded.

- Sending to ERP all the details of each batch loaded for automatic issuance of the document of transport.

- Automatically sending all the certificates associated with the packing list delivered by email to Customer.

- Statistical analysis on all shipments performed.

Processing management

- Automatic upload of work orders from in-house ERP systems or creation in STAIN+ of work orders (cutting, threading, calibration, etc.).

- Calculation and identification of cut batches.

- Tracking of heats and certificates from the parent batch and all the batches generated after processing.

- Loading of processed batches to warehouse and updating of inbound and outbound movements to ERP.

- Scrap and inventory accounting.

- Accounting of times and the operators who performed cutting operations.

- Cross-checking of work orders with products consumed, loaded, in stock and return of non-processed material to the warehouse.